Introduction

This is my first post in participating in Amy Johnson Crow’s 52 Ancestors in 52 Weeks a set of 52 prompts to write about your family history. I’m not sure I will make posts for all 52 weeks, but I will shoot for at least monthly. This post will serve to fulfill two of the prompts weeks 1) “I’d like to meet…” and 3) “Out of place”.

Meet Norman B Hyde

Norman Hyde is my great-grandfather. I’d like to meet him to see if he could break one of my biggest brick walls: Who is his maternal grand-father or my second great-grandfather? However, if he couldn’t do that, I’m sure he would be a fascinating person to talk with. I’ve found a wealth of information about him that will be summarized briefly.

I do have some doubts that he could provide information about his grand-father. He is probably either Samuel or John/Jonathan Latimer (guesstimate 1784-1817) and is rather mysterious. He died or disappeared when Norman’s mother, Francis Latimer (1807-1873) was about 10. His grandmother Jane McCutcheon (1788-1823) married second Daniel Shearer (1791-1874) in 1818. Their daughter Jane Maria Shearer (1819-1910) was an early member of the LDS faith and is quite well documented thus I’m quite sure of those relationships. I have several DNA matches with her descendants.

Norman’s Life

Norman was born 12 Dec 1844 in Groton, New York to Henry D Hyde (1085-1864) and Francis Latimer Hyde (1807-1873). He had three brothers and five sisters.

He served twice in the Civil War. The first term started 11 Oct 1861 as a Private in Company F, 76th New York Infantry. He was discharged 24 Sep 1862 at Washington, DC due to disability. He served with his brother Charles U Hyde (1827-1885) and his second cousin Charles A (1840-1863). Charles A died of injuries at Gettysburg. Note: Norman and Charles U were discharged due to disability before the Gettysburg battle. His second term was served beginning Feb 1864 as a Private in the New York 9th Heavy Artillery Regiment. He was discharged 6 May 1865 at McClellan General Hospital in Philadelphia.

Between his Civil War service he married Mary Augusta Sears. They had eight children between 1864 and 1884. The last was my grandmother, Mabel Augusta (1884-1963).

Post Civil War, Norman was an officer and/or member of several Grand Army of the Republic (GAR) Chapters.

Via several censuses and other records Norman had these occupations: Soldier, Blacksmith, Farmer and Teamster. He lived in several places in Tompkins County, NY and Potter and Tioga Counties, PA. In addition to the GAR, he was active in the Grange and local politics.

He died in Galeton, PA 8 Feb 1918 after being struck by a train.

Out of Place

The first real record of Norman I found was when he showed up in the Elisha Eldridge (1805-1867) household in the 1860 census. I was researching that family at the time and it made at least vague sense since I was aware that there were several marriages between the families. I thought perhaps they could have have been care takers. But when I started researching farther, he also showed up where is should have been. That was in his father, Henry D Hyde’s home. I should note that Elisha is my second great-grandfather.

Elisha’s home was counted 19 Jun, page 30

1860; Census Place: Groton, Tompkins, New York; Page: 30; Family History Library Film: 803868

Henry’s home was counted 13 Jun, page 4

1860; Census Place: Groton, Tompkins, New York; Page: 4; Family History Library Film: 803868

The Hyde and Eldridge farms were near each other, so I suspect Norman was visiting his sister, Ann who had married Palmer Eldridge.

source: https://freepages.rootsweb.com/~townofithaca/history/maps/1853/_P9D9543.jpg

Further out of Place

William Moe also appears to be “out of place” at the Eldridge home. There are two nearby Moe farms on the full version of the map above. Willam also appears in the home of Catherine Moe. Counted on June 16th.

1860; Census Place: Groton, Tompkins, New York; Page: 22; Family History Library Film: 803868

References

Seventy-Sixth Infantry Civil War Roster.

https://museum.dmna.ny.gov/application/files/6815/5240/1350/76th_Infantry_CW_Roster.pdf

Annual Report of the Adjunct-General of the State of New York for the Year 1897.

https://museum.dmna.ny.gov/application/files/4515/4834/3860/9thArtCW_Roster.pdf, page 197

Hyde genealogy, or, The descendants, in the female as well as in the male lines, from William Hyde, of Norwich

https://archive.org/details/hydegenealogyord02walw/page/1144/mode/1up

Railroad Accident Death 9 Feb 1918

https://www.newspapers.com/clip/88031288/railroad-accident-death/?xid=637

A completed bowl on the punty

A completed bowl on the punty

Amethyst Steam Bowl (approximately 7″)

Amethyst Steam Bowl (approximately 7″)  Color Application and “poking”

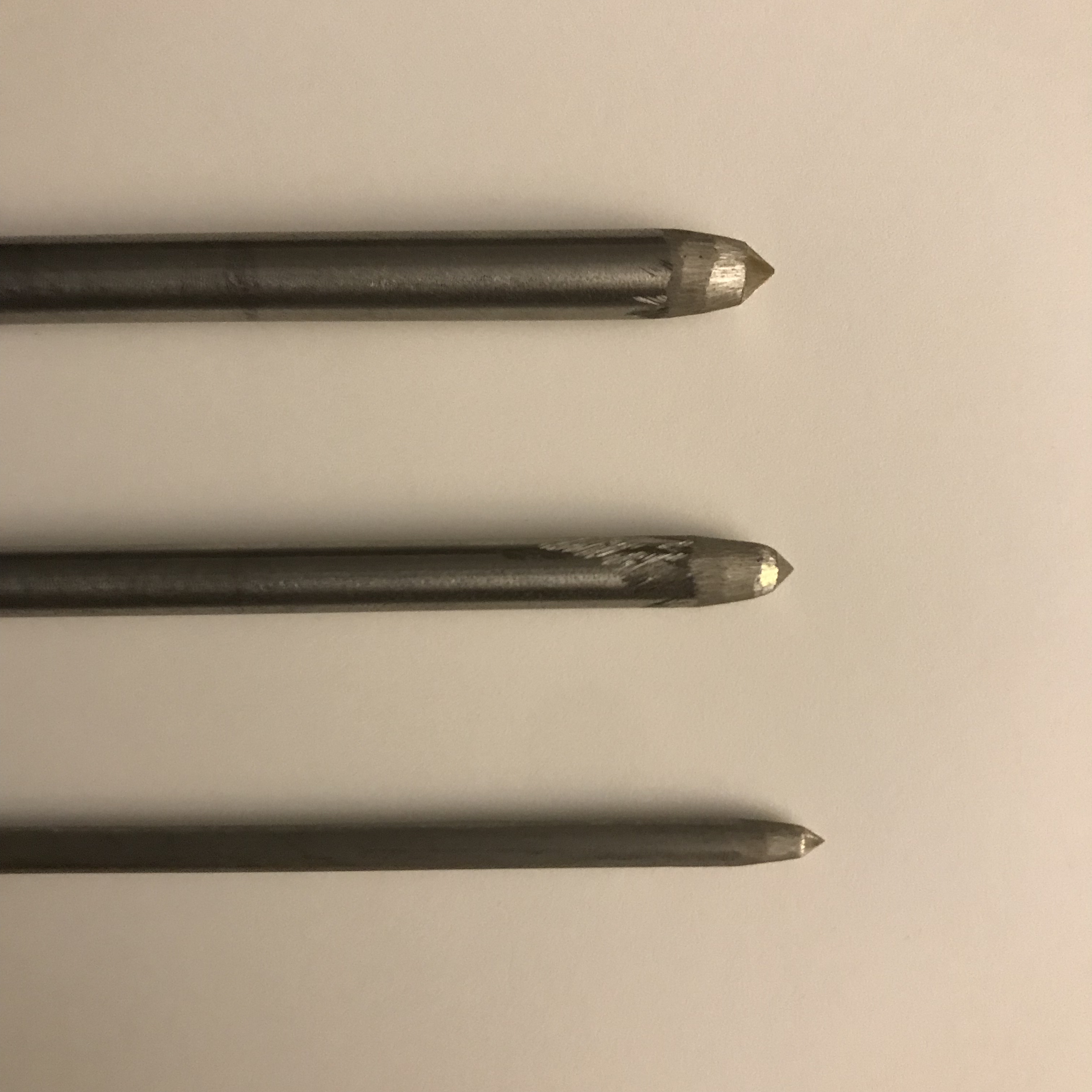

Color Application and “poking” Initial Pokers

Initial Pokers

Steam Stick

Steam Stick